Meet VitrimaxThe Reprocessable Thermoset

Intentionally Designedfor Circularity

RobustMechanicalPerformance

Infinitely Reshape Above Tg Without Liquifying

Optimized for PrepregCompression Forming

Infinite Reusabilityof Scrap AndEnd-Of-Life Materials

Recyclable By SolvolysisFor Recovery ofResin and Fiber

VITRIMAX™ by Mallinda is an infinitely recyclable platform chemistry revolutionizing composite materials. Designed to break the 20th-century paradigm of single-use engineering resins, vitrimers are a new class of polymer combining the mechanical performance of thermosets with the processability and logistical benefits of thermoplastics.

VITRIMAX™ by Mallinda is an infinitely recyclable platform chemistry revolutionizing composite materials. Designed to break the 20th-century paradigm of single-use engineering resins, vitrimers are a new class of polymer combining the mechanical performance of thermosets with the processability and logistical benefits of thermoplastics.

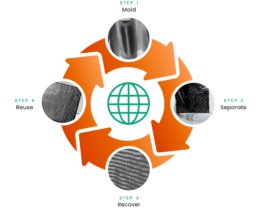

Mallinda’s VITRIMAX™ platform chemistry lengthens the lifecycle of materials that were previously unrepairable and non-recyclable. There is no material end-of-life, only an ongoing reincarnation cycle of usage opportunities.

Regenerative

Recycle in solution for recovery of resin & fiber, or in the solid state for uber facile recycling & reuse.

High-Strength

Formulated to meet or exceed mechanical performance of traditional epoxy resins.

Customizable

Highly tunable platform chemistry enables rapid custom formulation to suit specific needs.

Malleable

Reheat, remold & reshape without losing structural integrity or mechanical performance.

High-Performance

A lighter resin for improved weight savings with robust adhesion to a variety of fiber types including carbon, glass, & natural fibers.

Close the Loop

VITRIMAX™ was designed for end-of-life circularity, and for perpetual usage opportunities. Our chemistry stays active so that both fiber and resin can be recollected and reused through Mallinda’s patented recycling processes. Mallinda’s vitrimer lengthens the lifecycle of products that were previously unrepairable and unrecyclable.

Eliminate Waste

VITRIMAX™ can be restored, repaired or reformed an infinite number of times without ever losing its structural integrity or mechanical performance. Drive to 100% material utilization by using your scrap.

Improve Logistics

Compression forming of pre-cured materials can take as little as 20 seconds to make high performance, well-consolidated parts. Precured VITRIMAX™-based materials are indefinitely shelf stable under ambient conditions, saving on refrigeration costs and ultimately reducing the carbon footprint.

A Perfect Fit

VITRIMAX™-enabled products have unprecedented opportunities to customize for fit and comfort. Athletes are able to reshape products for a custom form, curve, or angle while maintaining the performance and impact strength of their gear.

Closing the Loop with Chemistry

VITRIMAX is a superior and sustainable material choice for polymeric and composite applications across industry segments. A product made with VITRIMAX is connected to a greater ecosystem of solution-oriented items diverting plastic and highly valuable fiber reinforcement out of landfills and directly back into new products with the exact same structural integrity and mechanical performance