PDF Presentations

Discover the key benefits and recyclable nature of vitrimers.

Technical Papers

New material: Vitrimers promise to impact composites

Strong and durable like thermosets, yet moldable and recyclable like thermoplastics, vitrimers are ‘malleable thermosets’ which are challenging the status quo in the composites industry. Mallinda, a startup company founded by some of the pioneering inventors of the technology, is developing malleable CFRPs for rapid (∼30 s) production cycle times.

Repairable woven carbon fiber composites with full recyclability enabled by malleable polyimine network

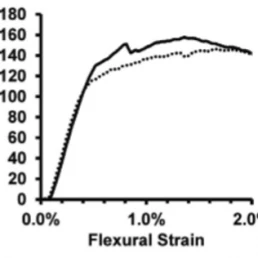

Carbon‐fiber reinforced composites are prepared using catalyst‐free malleable polyimine networks as binders. An energy neutral closed‐loop recycling process has been developed, enabling recovery of 100% of the imine components and carbon fibers in their original form. Polyimine films made using >21% recycled content exhibit no loss of mechanical performance, therefore indicating all of the thermoset composite material can be recycled and reused for the same purpose.

Heat Or Water-driven Malleability In A Highly Recyclable Covalent Network Polymer

A catalyst‐free malleable network polymer that can be reprocessed by application of either water or heat is prepared through imine chemistry. This material is recycled from a fine powder to a coherent solid with >100% recycling efficiency through several generations. It is also reprocessed at ambient temperature using only water, thus potentially leading to energy‐neutral green processing of the material.

Frequently Asked Questions

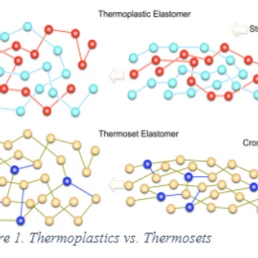

Vitrimers represent a new class of polymers based on dynamically exchangeable imine-linked polymer networks. Like thermosets, vitrimers are highly crosslinked network polymers. However, unlike thermosets which are permanently in a fixed form after curing, vitrimer chemistry yields a product that can be remolded. When heated above the glass transition temperature, the fully cured network polymer undergoes rapid dynamic covalent bond exchange within the polymer network. This allows for facile processing of thermoset materials that after being fully cured can be heated and reshaped. Upon cooling, the materials retain thermoset-like mechanical performance.

Vitrimer resins can give you the best of both thermoplastic and thermoset worlds.Vitrimer resins have the mechanical properties of thermosets and remoldability and more efficient recyclability of thermoplastics.

Mallinda is an advanced materials company that specializes in strategically engineering vitrimer resins. Our resins are then used to make carbon fiber reinforced composites (CFRCs). Our prepreg may be used in a wide array of applications; from sporting goods to automotive.

If we define the A-stage of an epoxy resin in which the material is flowing and soluble in certain solvents, the A-stage vitrimer resin is nearly indistinguishable to the A-stage of epoxy resins, making it easy to infuse with a pot life consistent with traditional epoxy resins (~6 h).

The B-stage of Mallinda’s vitrimer prepregs is different from traditional prepregs. In a traditional B-stage epoxy resin material, B-stage is identified as the point at which the material retains tack. To remain tacky, the resin is left partially uncured to enable molding. With a vitrimer resin, the material at B-stage can be fully cured (all of the epoxy crosslinked and reacted) and the material molded simply upon heating to the glass transition temperature. Therefore, vitrimer resin-based prepregs at B-stage are dry and tackless.

Vitrimer-based prepregs come fully dried and precured. As such, the materials do not require any refrigeration. When stored at approximately room temperature in a sealed container, the shelf life is indefinite.

The materials should be stored at room temperature (25C) in a sealed container or bag.

Mallinda has resins available with a Tg range from ~20 C – ~240 C, depending on your needs. We are actively working on research and development to meet the needs of the industry.

Mallinda’s resin can be recovered using reagents utilized in the resin synthesis. This is key to (1) allowing a cradle-to-cradle, energy-neutral system for the recovery of resin and woven/full-length fiber that does not require the use of heat nor the introduction of any additional chemical components outside of our formulations for recycling; (2) enabling full recovery and re-usability of our resin. This is quite different from solvolysis, which only works to recover resin from uncured (B-staged) prepreg by the introduction of an organic solvent. This can result in generating additional chemical waste and will not work on materials that have been exposed to heat or air and have begun to cure. Pyrolysis uses excessive heat to burn away resin and allows for the recovery of shredded short fiber carbon fiber.

Wrong. Vitrimers are a new class of polymer that has a high level of crosslinking, like a thermoset, which enables the material to have high mechanical performance. Vitrimers all have a strategically engineered Tg that enables remoldability. Meaning, after a vitrimer has been fully cured, and epoxy crosslinked it can be heated to Tg and remolded or compression molded. A thermoset, on the other hand, is permanently fixed in position after is has been fully cured and crosslinked.

Our vitrimer resins are highly robust and chemically resistant. Strongly acidic environments should be avoided.

Cycle time can be as quick as seconds to minutes (< 5 min).