Responsibility: Circular economy

A Leader in Regenerative Materials

With the introduction of VITRIMAX™, vitrimers have become a commercially relevant engineering solution. The mechanical performance of VITRIMAX™ is on par with structural engineering polymers like thermosets, and are coupled with a sustainable, zero-landfill end-of-life solution. Mallinda’s VITRIMAX™ platform chemistry lengthens the lifecycle of materials that were previously unrepairable and unrecyclable. For products made with VITRIMAX™, there is no material end of life, only an ongoing reincarnation cycle of usage opportunities.

Recyclable Advanced Carbon Fiber Composites

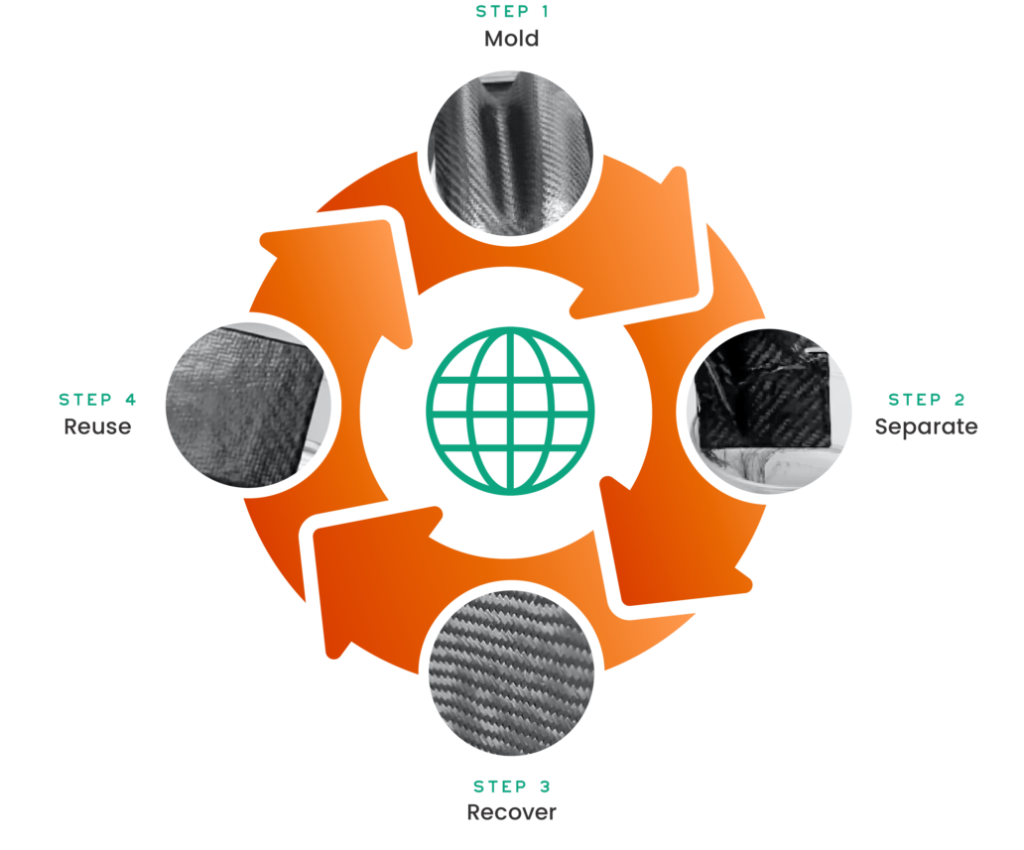

Mallinda has developed a completely closed-loop system for the recovery of both polymer and carbon fiber from CFRC end-of-life products and scrap materials. Our patented recycling process takes advantage of the reversible chemistry of our material, generating no excess waste, and using almost no energy. Both the recovered carbon fiber and the recovered resin can be reused to make fresh composite materials.

Composite headlight housing at end-of-life

The product is immersed in recycling solution

spontaneous depolymerization of the polymer network

fiber and resin are isolated and recovered

Reprocessable For the Circular Economy

VITRIMAX™-enabled products may be recycled many times over. The fully cured resin may be isolated using precursors from the initial resin synthesis. After isolation, simply balancing the resin formulation as needed enables full reusability.

The polymer may also be ground into a powder and reformed into new shapes with heat and pressure. This both increases the input lifetime vis-a-vis recycling and reduces the energy required during re-purposing.

In addition, Mallinda’s ability to implement solid state thermoforming could revolutionize production of powder-based composite materials.

Subscribe to our newsletter!

Stay up to date with our monthly newsletter, including news and product announcements.