Product: The Technology

Form the Future

Mallinda is a supplier and developer of polyimine-based Vitrimer resins known as VITRIMAX™. VITRIMAX™ represents a new platform chemistry based on dynamically exchangeable imine-linked polymer networks. Like traditional thermosets, VITRIMAX™ is a robust highly crosslinked network polymer. Unlike legacy thermosets, the VITRIMAX™ platform yields a product that can be remolded,

but only when heated above the glass transition (Tg). Upon cooling, internal stresses are relaxed away, and the materials retain thermoset-like mechanical performance. The reversible nature of VITRIMAX™ enables covalent welding, molding, reshaping, solution-based and solid state, closed-loop recycling of fully cured materials. VITRIMAX™ chemistry is highly tunable to meet the specific thermomechanical requirements across industry segments.

A Drop-In Technology

- VITRIMAX VHM™ offers competitive mechanicals as well as end-user customizability

- VITRIMAX VHM™ is competitive with today’s industrial epoxy-based thermoset resins that have a glass transition temperature of 130°C.

- The system is a 2-part hot melt ready resin ready as a drop-in solution for various existing prepregging processes.

Customizable Options

- VITRIMAX™ can be formulated to have a range of vitrimer transition (AKA Tg) temperatures, processing viscosities, and mechanical properties.

- The vitrimer transition, or Tg, can be programmed from 20°C-170°C, formulated elastomeric to crystalline, and Mallinda offers customized development in strength, toughness, adhesion, resistance, and more.

- Get the perfect resin for your application.

Chemical Recycling of End-of-Life Products

Mallinda has developed a completely closed loop system for the recovery and reuse of fiber and resin from fiber reinforced composites. Our patented recycling process is energy efficient; taking advantage of the reversible chemistry of VITRIMAX™, generating no excess waste. Both the recovered carbon fiber and the recovered resin can be reused to make fresh composite materials. VITRIMAX™-based materials may be recycled many times over.

Key Advantage: Reduce your CO2 footprint and be truly sustainable.

Mechanical Reuse of Scrap and End-of-Life Products

VITRIMAX™ resin chemistry stays active, even after cure so all scrap can be used for discontinuous composite part production, enabling 100% material utilization to form high-performance parts. Resin alone, or VITRIMAX™-matrix composites can be mechanically processed and reformed into high-performance second-generation materials using heat and pressure, yielding no loss in mechanical performance, unlike traditional thermoplastics.

Key Advantage: Eliminate composite waste.

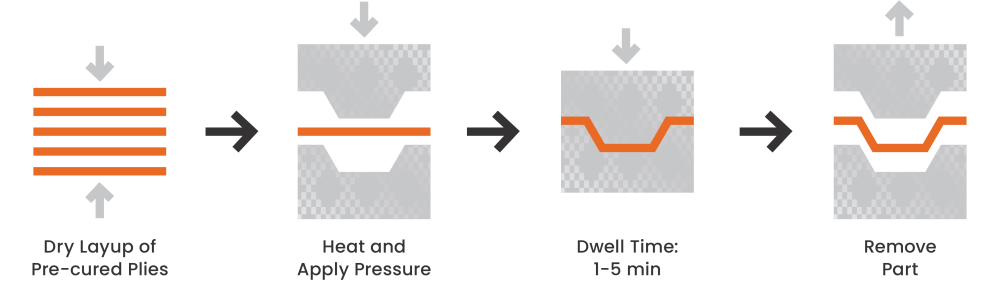

Rapid Pre-Cured Thermoset Compression Forming

Despite clear logistical advantages – no legacy thermosetting resin can be pre-cured for shelf-stability. Due to the active covalent bonding in VITRIMAX™ chemistry, compression forming of pre-cured materials can take as little as 20 seconds to form high-performance, well-consolidated parts. Precured prepreg sheet stock have no requirement for refrigerated storage and transport, nor any hazardous handling or shipping constraints/costs. Precured VITRIMAX™-based materials are indefinitely shelf stable under ambient conditions and can be processed much like thermoplastics; saving refrigeration costs and reducing carbon footprint.

Key Advantage: Improved Logistics

End-User Reformability for Custom-Fitted Gear

VIRTIMAX VHM™ composite materials can be reshaped above the cured tg, and have been optimized for home use, for end user customizability. Athletes can infinitely adjust the fit or geometry of VITRIMAX™-enabled sports gear in boiling water (if the cured tg is below 100°C) until they get the perfect shape or fit.

Key Advantage: Eliminate the need for custom tooling and enhance customer satisfaction with the perfect fit.

Subscribe to our newsletter!

Stay up to date with our monthly newsletter, including news and product announcements.